Supermarkets and Retail

The major focus of companies targeting the supermarket sector is based on three key strategies: Ensuring a balance between good value for money, customer service and guaranteeing a wide range of products available in store through flexible and efficient logistics.

In the same way, responding to new consumer habits and the experience of making a complete purchase in the shortest possible time, at reasonable prices and in a convenient way puts logistics automation at the centre of the equation for success.

Now more than ever, the current market leads us to develop more efficient logistics solutions and thus offer a proposal of high value, quality and efficiency to our customers. For this, we have designed our own logistics model aimed at the Supermarket and Retail sector for large, medium and small companies that decide to make a commitment to their future.

Trends in the supermarket and retail sector:

- New customer habits and their high level of information on environmental and health issues, etc.

- Digitalisation of shops and processes

- High flexibility in the light of fluctuations in demand

- Agility in the checkout process

We have our own software designed exclusively for the Supermarket sector, which guarantees fast, efficient and versatile multi-reference automatic order picking.

What can we offer to improve your intralogistics system?

Now more than ever, the current market leads us to develop more efficient logistics solutions and thus offer a proposal of high value, quality and efficiency to our customers. For this, we have designed our own logistics model aimed at the Supermarket and Retail sector for large, medium and small companies that decide to make a commitment to their future.

- Automated warehouses with palletised or boxed products.

- Systems for omni-channel order picking: orders for retail shops, e-commerce, home delivery and/or click & collect.

- Palletising robots

- Flexible solutions for different volumes and types of orders.

- Suitable environments depending on the nature of the products: temperature controlled and/or frozen (down to -35°C).

- Thanks to the u·mind universe, warehouse management will be simplified, optimised and have the required sophistication to help with inventory control, order picking, dealing with order peaks and troughs at different times of the year, respecting FIFO models, warehouse entry and exit within a 24-hour period, etc.

Solutions for the Supermarkets and Retail sector

Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

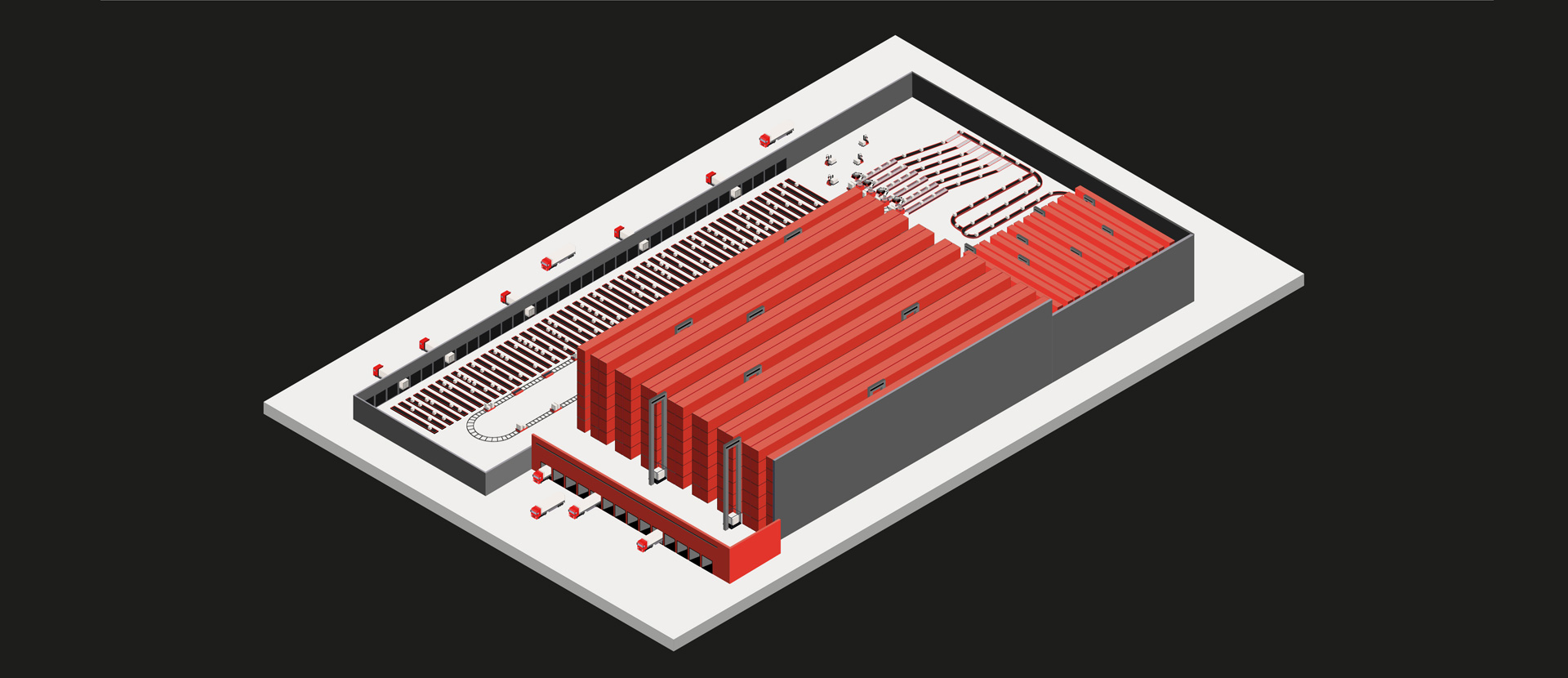

Automated dry, temperature-controlled and/or frozen storage

Automated warehouse for palletised products:

Automated warehouse for products in tray/box/case:

- Click & Collect and/or Drive services: M-Shuttle, Pick To Light and Picking Cart, among others

Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: layer robot, IK Pal robot, anthropomorphic robot, unstackers and box stackers, among others.

- Sequencers: M-Shuttle, FSS/SQS, light load conveyors, crossbelt sorter.

- Conveying light loads: descrambling, sorters, light load conveyors

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

Shipping to customer

- Sorting for shipping (STV and/or Shuttle Cart)

- Output buffers to maintain the cold chain (Unit Load)

U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

-

1. Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

-

2. Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

-

3. Automated dry, temperature-controlled and/or frozen storage

Automated warehouse for palletised products:

Automated warehouse for products in tray/box/case:

- Click & Collect and/or Drive services: M-Shuttle, Pick To Light and Picking Cart, among others

-

4. Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: layer robot, IK Pal robot, anthropomorphic robot, unstackers and box stackers, among others.

- Sequencers: M-Shuttle, FSS/SQS, light load conveyors, crossbelt sorter.

- Conveying light loads: descrambling, sorters, light load conveyors

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

-

5. Shipping to customer

- Sorting for shipping (STV and/or Shuttle Cart)

- Output buffers to maintain the cold chain (Unit Load)

-

6. U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

Discover our success stories

SCA Normande Leclerc

The French leader in retail sales to end consumers and a pioneer in intralogistics automation, relied on ULMA for its automated warehouse.

More information

INTERMARCHÉ

Ambitious Logistics Automation Project for Intermarché

More information

EROSKI Elorrio

EROSKI’S new automated system is unlike any other in Europe

More information