Food and Drink

Purchasing habits are constantly changing. There is a demand for an increasing variety of items and an expectation that the shopping experience will be pleasant with a high availability of products. Omni-channel retailing is now a reality, and e-commerce is a channel to be taken into account in distribution centre processes.

To achieve this, it is essential for food and beverage producers and distributors to have an efficient supply chain.

The food and beverage industry works with very sensitive products, for which it must guarantee hygiene measures, optimal time management, due to expiry dates, and temperature management (dry, cool, temperature-controlled, frozen) to ensure the cold chain is not broken at any time. In this context, intralogistics flows must meet strict requirements.

In ULMA’s automated systems, all processes are controlled and managed by u·mind, our logistics software suite, maximising the efficiency of the automated installation. u·mind allows you to permanently monitor your stored products and provides an overview of your BBE and BBD data.

Trends in the food and beverage sector:

- Increasing demand for a variety of purchasing options

- Rising demand for fresh produce

- Proliferation of food and beverage of products. Demand for a wider variety of products

- Sector with strict food safety regulations

- Omni-channel retailing: shopping in department stores, small shops, e-commerce, etc.

- Demand for more local and organically sourced products

Due to its nature, the food supply chain presents several challenges: the importance of not breaking the cold chain, fresh products and managing expiry dates, among others.

What can we offer to improve your intralogistics system?

- Automated warehouses with palletised or boxed foods.

- Systems for omni-channel order picking: orders for retail shops, e-commerce, home delivery and/or click & collect.

- Palletising robots

- Flexible solutions for different volumes and types of orders.

- Suitable environments depending on the nature of the products: temperature controlled and/or frozen (down to -35°C).

- Thanks to the u·mind universe, warehouse management will be simplified, optimised and have the required sophistication to help food and beverage companies with inventory control, order picking, dealing with order peaks and troughs at different times of the year, respecting FIFO models, warehouse entry and exit within a 24-hour period, etc.

Solutions for the Food and Drink sector

Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

Shipping to customer

- Sorting for shipping (STV and/or Shuttle Cart)

- Output buffers to maintain the cold chain (Unit Load)

U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: layer robot, IK Pal robot, anthropomorphic robot, unstackers and box stackers, among others.

- Sequencers: M-Shuttle, FSS/SQS, light load conveyors, crossbelt sorter.

- Conveying light loads: descrambling, sorters, light load conveyors

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

-

1. Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

-

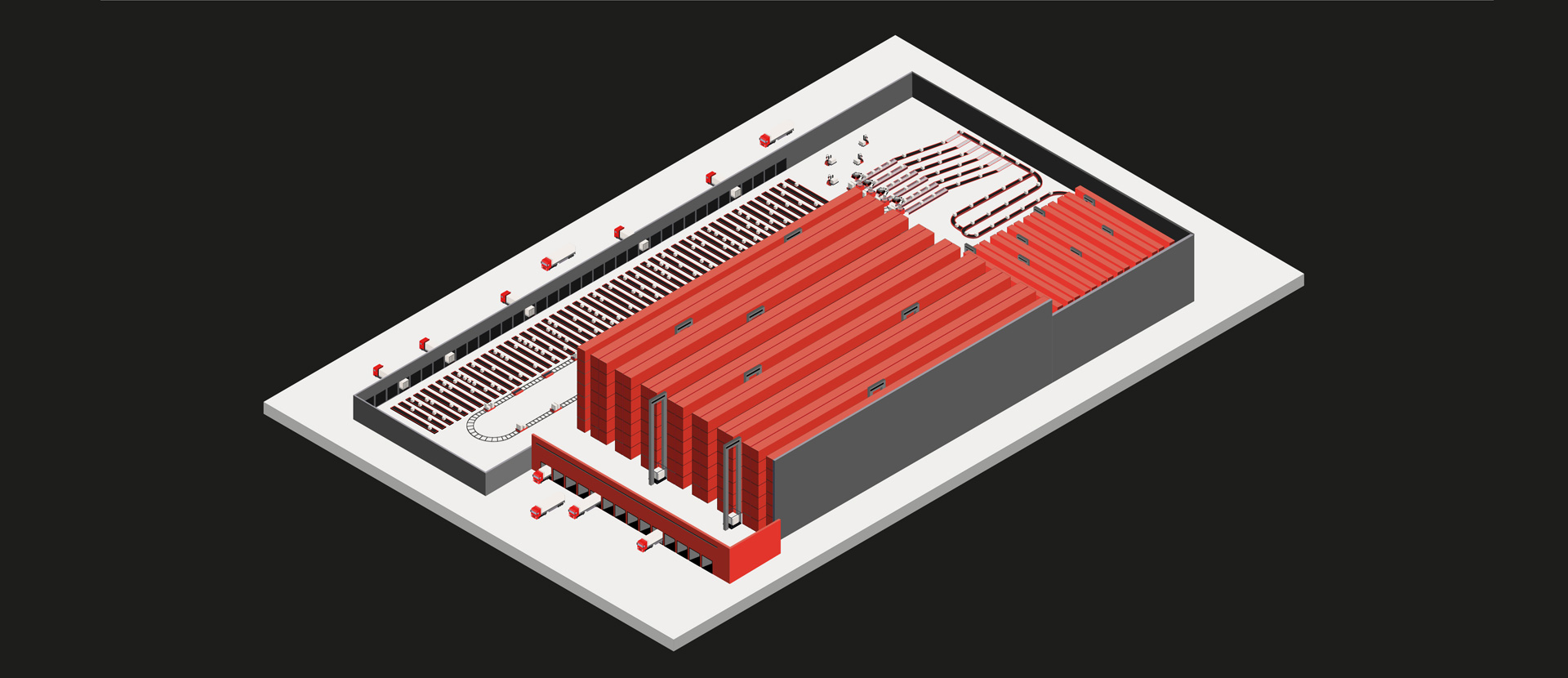

2. Automated dry, temperature-controlled and/or frozen storage

Automated warehouse for palletised food and beverages:

- Stacker crane: Unit Load

Automatic storage for food and beverages in tray/box/case:

-

3. Shipping to customer

- Sorting for shipping (STV and/or Shuttle Cart)

- Output buffers to maintain the cold chain (Unit Load)

-

4. U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

-

5. Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

-

6. Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: layer robot, IK Pal robot, anthropomorphic robot, unstackers and box stackers, among others.

- Sequencers: M-Shuttle, FSS/SQS, light load conveyors, crossbelt sorter.

- Conveying light loads: descrambling, sorters, light load conveyors

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

Discover our success stories

ENTREPINARES

Logistics dedicated to product quality

More information

BONDUELLE

Logistical system at controlled temperatures

More information

PANSTAR

Consolidated logistics for grupo Panstar's pre-baked bread and baked goods thanks to automation

More information